|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

Detecting tire slip is done a variety of ways. Some units use wheel speed proximity sensors mounted on the wheels to detect a difference in wheel speed between the front and rear tires, while others compare ground speed to rear wheel speed. Still others monitor a speed signal indicative of engine RPM and use software to check the rate of change of this RPM-if it exceeds a certain rate of change (indicating the tires are slipping too much), then engine power is affected. For example, flywheel teeth can be counted to get this rate of change of engine speed, as can transmission gear teeth, or closely monitoring a tachometer signal. Once tire slip is detected, electronic methods are used to reduce the engine power to the wheels. As one ETC manufacturer stated, "You can take away about 15 percent of an engine's HP with no indication it is being done. You can take more but you get into indicators like sound (engine note changes), temperature of the exhaust (increasing), or fire coming out the exhaust pipes (unburned fuel}." Also, engine cylinders may be randomly dropped (controlled misfiring), ignition timing can be retarded a little at a time depending on the amount of tire slip, or electromechanical actuators may be applied once excessive tire slip is noted. For example, Racetronics (ph: 610-759-8217) has actuators that apply/release the rear brakes, or manipulate the throttle to manage the engine's output for best traction. Davis Technologies (ph: 828-645-1505) and Tri-Mark Performance (ph: 608-643-0088) market ETC using management of ignition timing, or misfiring. ETC PACKAGING EVOLUTION

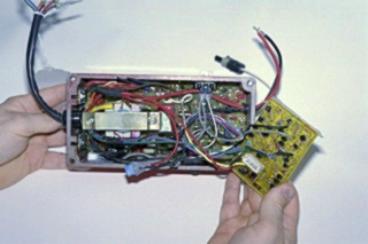

A next step was to control the activation / deactivation of the timing

retard circuit, or RPM limiter circuit via a "window switch," which

turns the circuit on at one preset RPM and turns it off at another.

The racer didn't have to be involved. Sometimes this timing retard circuitry,

or controlled misfire circuitry, would be extracted from the factory

packaging and installed elsewhere in the car (say for example, in the

seat foam), if tech inspectors decided to open up spark boxes and see

if they were just a bit too stuffed with electronics. |

||||||||||||||||||||||||

|

Copyright 1999-2001, Drag Racing Online and Racing Net Source |

||||||||||||||||||||||||