I have been busy in the garage almost every

night getting the "Project 4-Link" and "Back-2-Basics"

Vega ready for 2004. First comes the disassembly,

then the inspection of welds, bolts, etc. to

make sure everything is structurally ready.

The "Project 4-Link" chassis was ok, but will

need some "helmet bars" put in to meet the new

chassis spec. You will notice in the photo there

are two small bars there now but when the chassis

was built there was no rule on helmet bars.

We will install the new ones just below the

existing smaller ones. I do not have a TIG welder,

or the skill to operate one, so I will be getting

friend and new chassis shop owner Danny Fox

to bring his over to weld in the bars once Andy

and I get them cut to size and notched to fit.

This is the helmet bar

tubing kit as we received it from Jim Pulliam

Dragsters. 1" x.058 4130 chrome moly steel tubing.

We will cut them carefully and notch them for

an exact fit before they are tig welded in.

Then the chassis will get recertified this spring

by IHRA and NHRA.

I also noticed my safety harness will expire

in June 2004 so I am sending them in to be re-certified.

The neck collar is pretty ragged and will be

replaced, as will the driving shoes that are

almost worn out. Be sure to check or replace

any safety harness bolts with new grade eight

hardware and locking nuts. If there is one set

of bolts you don't want to fail when you need

them it is the safety harness mounting hardware.

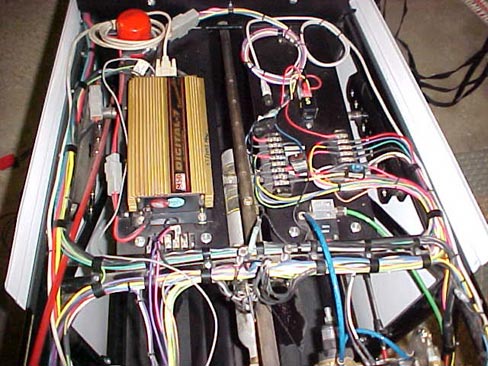

As I inspected the wiring I noticed that I

had far too many splices in the wires. The problem

areas are around the transbrake solenoid and

the electric water pump. After three seasons

and some "emergency pit repairs" it is time

to fix it right. I will cut out all the splices

and wire in a couple AMP weather tight connectors.

I will also wire the connectors to my spare

transbrake solenoids, the Vega transbrake wires

and the spare water pump motor. That way if

there is a problem in the middle of eliminations

we can switch out solenoids or water pumps in

a matter of minutes without cutting wires and

splicing new ones in. I should have done it

that way the first time, but later is better

than never.

The main wiring has "weathered"

the three seasons very well. Not one glitch

with how well the MSD Programmable Digital 7

ignition has performed. Taking our time when

we first assembled the car and wired it and

drawing up a good schematic has saved hours

of time over the past few seasons, especially

when I got the NHRA "wiring inspection" at Topeka

last Spring.

|