|

The move to Top

Dragster is almost complete!

4/8/04

he

upgrades we had to make to "Project 4-Link"

are just about complete. The engine is done

and has returned from the dyno. The Jim Pulliam

chassis has received the helmet bars as needed

to re-certify, the transmission has been rebuilt

and received some stronger parts, and the tire

and wheel package has been changed to handle

the additional power. The throttle stop has

been removed for the first time in three seasons

and to not worry about hitting the 8.90 index

every run will be a nice change. Back to running

it flat-out and dial it to run that way. he

upgrades we had to make to "Project 4-Link"

are just about complete. The engine is done

and has returned from the dyno. The Jim Pulliam

chassis has received the helmet bars as needed

to re-certify, the transmission has been rebuilt

and received some stronger parts, and the tire

and wheel package has been changed to handle

the additional power. The throttle stop has

been removed for the first time in three seasons

and to not worry about hitting the 8.90 index

every run will be a nice change. Back to running

it flat-out and dial it to run that way.

The entire process has been pretty smooth and

I have a lot of people to thank for their help

and efforts to put our "Project 4-Link" into

Top Dragster. I couldn't have done it without

their assistance, advice and terrific components.

This month I am going to cover the decisions

surrounding the engine and the assembly of the

engine by Jay Roeder at Roeder Performance Machine.

I am also going to cover the details to watch

for and to check during assembly and finally

the actual dyno test of the 572" Mopar at Stealy

Machine in East Moline, IL. Time for all the

time and efforts to either show their stuff

or...

We arrived at Jeff

Stealy's shop in East Moline, Ill. for the

dyno session. We found the shop very organized

and full of the best equipment available.

Seeing a couple of dozen race engines "in

the works" is always reassuring to me that

the shop is "race ready". |

We hauled the engine over to Jeff Stealy's

dyno on a Friday morning and it was hooked up

and ready to go in about an hour. It is always

interesting hooking up my belt drive to someone

else's dyno. Aeroquip would be proud of the

trick work we did with some hoses, adapters,

reducers and wire ties. We started the test

session with the single alcohol King Demon we

ran the last two seasons in Super Comp. This

will let us see the gains in just the engine

package. It was on there for a warm-up and two

pulls. Last year that intake and carb made a

peak rating of 817 HP and 710 ft./lbs. of torque.

The best pull with the 32 additional cubic inches,

about 1/2 a point higher compression and a different

camshaft netted a best pull of 835 HP and torque

increased to best of 754 ft./lbs @ 5500 rpm.

A pretty substantial gain for having the exact

same cylinder heads on it with no changes but

new Ferrea valves.

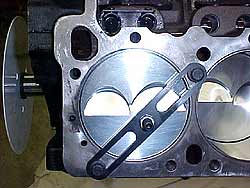

Finding Top Dead

Center is the first step in any camshaft

installation as you have to start at the

right point to get it degreed in correctly.

Jay uses this "positive stop" method to

be sure he is at TDC. |

Then we took about an hour off to remove the

alcohol King Demon and install the new Indy

tunnel ram and the matching King Demon TR 1090s.

After some interesting "design work" to get

the tunnel ram linkage setup, we made a pull

with timing set as it was with the alcohol (28

degrees). The results were outstanding and surprising

to everyone peeking through the dyno room window.

The first pull was 899.9 HP and just over 790

ft./lbs. of torque! I never dreamed it might

actually go over 900 HP. We made a back-up run

to make sure it was the same and it was. Then

we made a couple of small timing changes.

|