- One other thing we made that really made it

easier is a homemade fixture made out of 1”x1”x1/8” angle

iron that bolts to the pan rail and has a 2” piece

of pipe on the end that goes into the head of our portable

engine stand. Easy to rotate and stable. There are commercial

units available but for two or three times a year a homemade

one will work fine.

ADVERTISEMENT

|

I will do my best

to keep this short but there are so many details that it

is difficult. I cannot emphasize enough how useful Carl Munroe’s

Power-Glide Handbook is. It literally took me from rookie

to confident with his excellent instructions that are aided

by hundreds of great photos.

First thing to do is drain the transmission the best you

can. Then remove the pan and note the amount of debris inside

-- a lot of shiny debris should prompt you to look closely

at bushings, gear sets and have the torque converter freshened.

Next remove the two bolts holding the filter on. The trans-brake

solenoid and the spool valve that goes against the solenoid

are next. The valve body can now be removed. There are three

bolts that go through it at the front of the valve body and

four at the rear of the valve body. When you lift it out

just wiggle the small steel tube that runs from the valve

body to the case and it will come out with the valve body.

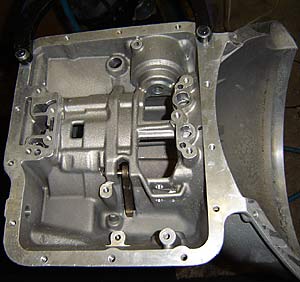

This is the bottom view of an empty case (this

one is a Dedenbear SFI certified case.)

|

Now you can do your first measuring. I have a small

piece of angle iron I clamp to the bell-housing area

and a dial indicator with a magnetic base that attaches

to it. Line up the dial indicator so it can measure movement

on the end of the input shaft. Push down on the shaft

and try to get the dial indicator set to zero at that

point. Then push in on the output shaft and read the

dial indicator to see how much “input shaft end-play” you

have; write it down for later reference. |

|