|

<<

PREVIOUS PAGE

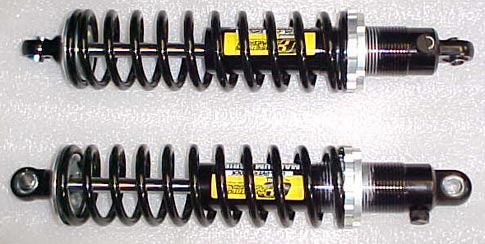

This is the assembled

Magnum Series shock with the spring installed.

The 12-position adjustment knob can be seen

on the right side of the shock absorber.

The Magnum Series shocks will give us 12 easy

adjustments and should allow us to be up and

racing right away with consistent launches.

We did a little guess work on the coil-over

springs, but went with Competition Engineering

C2555 (100 lb.) springs. We might be a little

too soft, but until the car is assembled and

we start testing I had to start somewhere. Don't

forget to get a coil-over shock adjusting tool;

without one changing the ride height and spring

pre-load is a real hassle. We got the Moroso

#62030 for $20.00. The shocks were easy to assemble

and fit perfectly.

The next project I had to get started on was

the WIRING. This can either be a fun project

or a nightmare. It basically boils down to your

attitude before you start and how well you planned

ahead. This was about the tenth car in recent

years I have totally re-wired. Your plan should

start at the batteries and go to the water pump

and include everything in between. Here are

some basic tips I would recommend.

- I DO NOT try to make my wiring look like

the ones you see on $100,000 magazine project

cars and even some race cars that were done

professionally. That type of wiring with the

tight wire looms and hundreds of harness clamps

and trick $60.00 plug-ins are just TOO MUCH

for me.

- I want simplicity so it is easy to repair

or change and economical so I can afford to

do it in the first place. I can afford a little

extra time long before I can afford a bunch

of $20.00 connectors and special tools that

are needed to install them. Besides, I can't

remember the last time the wiring on one of

my drag cars ever got soaking wet, so why

do I care if I have weatherproof connectors?

- Find a good supplier for different colors

of automotive wire. I use a GPT standard wire.

It has a PVC jacket and is the most common

wire available. There are a couple upgrades

from the PVC jacket if you choose to give

your car the "Cadillac treatment." There are

three types of wire that have a jacket that

is resistant to oil, grease and acids. They

are also designed for use in a higher temperature

environment. The SXL jacket is standard thickness

(like the GPT), the GXl is a thinner wall

jacket and the TXL is an extra thin jacket.

The conductor is the same the difference is

in the protective jacketing (insulation).

I use Waytek, Inc. for my wiring supplies.

Call them at 800-328-2724 to get a catalog

or go to their website (waytekwire.com) to

see what they have. They shipped me everything

I needed the next day and the order was complete.

They also have a great selection of crimping

tools and heat guns for the shrink tubing.

- I decided to use a readily available switch

panel for Back-2-Basics. I spent some time

looking at what was available and I chose

the Moroso #74180 because it had quality switches

with amount of circuits I needed and best

of all it comes with 20 amp circuit breakers

rather than fuses. It retails for about $125.00

and you would be hard-pressed to make a copy

of it for that price if you bought individual

components.

- One thing to keep in mind when you do the

switch panel wiring is a rule that is sometimes

overlooked by the car builder, and then some

"panic wiring" takes place when you won't

pass tech inspection. The power to your electric

fuel pump must come from the ignition switch.

Wire the power to the fuel pump switch from

the "on" position of the ignition switch.

That way when you turn the ignition off the

fuel pump also turns off. For me it means

one more thing I don't have to remember. I

leave the fuel pump switch "on" all day, but

it only runs when I turn the ignition on.

Nothing more embarrassing than pulling into

the waterbox and the car dies and after 10

seconds of panic you remember you forgot to

turn the fuel pump switch on. Been there,

done that.

NEXT

PAGE >>

|