Putting the Vega in the “Double-Duty” Mode

By Jok Nicholson

6/16/04

![]() his is something

we are doing not exactly by choice but because the 572 in the “Project

4-Link” is out having some repair done to it. It is necessary if Andy wants

to race right now. There was a little extra prep we did to be able to run two

brackets with the same car but nothing major.

his is something

we are doing not exactly by choice but because the 572 in the “Project

4-Link” is out having some repair done to it. It is necessary if Andy wants

to race right now. There was a little extra prep we did to be able to run two

brackets with the same car but nothing major.

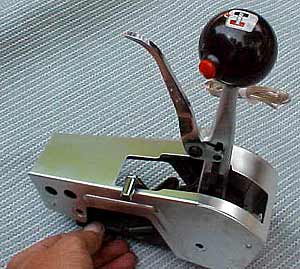

This is the Hurst Quarter Stick and components. Top quality piece that work for us for years. |

The first thing we had to do was look for any weak links that might give us problems later. The first thing we looked at was the cooling system for the engine and especially the transmission. The only thing we did to the engine was to put a restrictor in the thermostat housing. It has a 7/8” hole in it. This does a couple of things for us. It holds the water in the block a little longer with the pump running and this means the water can absorb more heat. On the other side of this is the fact that the water is in the aluminum radiator longer and it has more time to cool off. If you are having problems keeping your engine cool or cooling it between rounds, try to slow the water down. You might be circulating it so fast it doesn’t have time to absorb any heat from the block and heads. We also installed a Shogun “Tik-Tok” switch. This switch alternates the water pump and fan. It actually cooled us down faster and saved the batteries because both units weren’t running at the same time. Do NOT use the Tik-Tok during a run, just for cooling down between rounds.

Second we have been having problems with our old, old Hurst Quarter-Stick shifter. It was old enough that replacement cables did not attach properly and we had welded, brazed and epoxied it several times. I felt like double-duty could do it in. We made a call to Mr. Gasket ‘Hurst Shifters and we procured (begged and pleaded) a new Quarter Stick shifter. I did learn they can be used for both the two-speed Powerglides and three-speed transmissions. The shifter came with all of the correct brackets, fasteners and a heavy duty cable—a nice piece for about $150.

Installation was a snap. It took me about one hour and that included taking the old shifter out of the Vega. Adjustment was simple as well. I put the trans lever in neutral and the shifter in neutral and simply adjusted the threaded coupler on the end of the cable until it slid into the hole on the shifter arm. I plugged in the neutral safety switch wires from the old shifter and it was ready to go. Be sure to check the neutral safety switch operation. The starter should only spin if the shifter is in neutral or in park. Adjusting this is easy but mine worked great right out of the box. That is one more thing I am beginning to like about Chevrolet products, they fit the first time!

I love the new “side-winder” shifter knob and button. Makes holding the line-lock a lot easier and more comfortable. |

I also installed one Autometer electric oil temp gauge but added a twist. I bought an extra sending unit and put one in the engine oil pan as well as the transmission pan. I hooked up the sending unit wires to a double-throw toggle switch (3 position). With the switch in the middle position (off) the gauges are off. Flip it up and it reads trans temperature and down gives you an engine oil temp reading. Both temperatures are critical to being able to make consistent dial-ins in any bracket racing, but when you are running in two classes it is even more important. We like to see the engine oil at least 160 degrees and if it gets to 210 we start spraying water and running our vacuum cleaner/blower hose over the oil pan. In the trans we like to see about 160 to 200 degrees and when it gets to 210 or above we run the small fan. We put on the trans cooler and also blow fresh air over the converter from below with our converted small vacuum cleaner/blower.

It is actually a lot of fun doing double duty. I come back from the No Box run and hop out and Andy climbs in with delay box in hand so it can be plugged and ready for the Box class. So far I haven’t screwed up and ran on the bottom with a delay box in there … I’m sure if I do I will hear about it! I was hoping it was OK if “old guys” got a little advantage … OK, I didn’t really think that. Between switching helmets, adding fuel and being in the right place at the right time, it keeps you hustling and that is the fun part. Not sure if we can keep up if we both go to the finals, but I hope we have that problem this weekend.

All of this would not be possible without the help of a lot of great sponsors on the “Back-2-Basics” project car. The latest to join our team is Ollie at Mr. Gasket/Hurst shifters and they are joined by these great companies: Stan at Ohio Crankshaft Co; Traci at J-W Performance, Rick at Moroso, Joe at MSD, Doug at Demon Carbs, Kyle at Aeromotive, Bruce at Hoosier, Stan at TCI, Ron at Autometer and of course Jeff at Dragracingonline.com for the reliable 383” small block Chevy.

When you choose products for you race car or street machine I hope you will consider products by our great sponsors.

This is the shifter after installation; all that is left is to snap the aluminum cover on it. |

Well I have to go get the “Back-2-Basics” Vega ready for a big race

this weekend at Cedar Falls. Now if it will ever quit raining I can put all

these “little tricks” to work on Saturday night. ![]()

Copyright 1999-2004, Drag Racing Online and Racing Net Source