|

|

Recently, to commemorate the millennium,

I began a series of articles posted on our web site, www.iskycams.com,

entitled “Tech Tips 2000.”

The first ten or so are under the heading

“Modern Myths of High Performance.” I decided

to write them because I didn't necessarily enjoy repeating

myself

over and over in order to undo the misinformation rampant

in our industry.

So, like “Tech Tips 2000,”

Cam Session is intended to set the record straight with

the truth, the whole truth and nothing but, so help me.

Ron Iskenderian: will be setting

the record straight in each issue of Drag Racing Online.

If you have any questions concerning cams or valvetrain

components or tech, just email camsession@racingnetsource.com

|

|

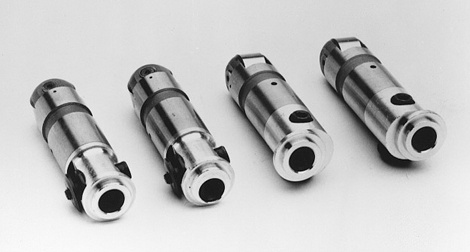

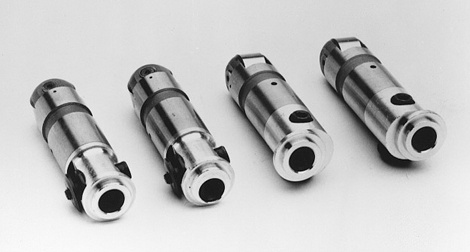

Roller Lifters:

Keep 'Em Rolling Longer

Most racers are aware of the advantages of roller lifters.

For those who are not, a brief review is in order. Roller cams and lifters

are employed today in all-out racing engines where valve lift/area requirements

preclude the possibility of employing a flat tappet (solid lifter cam).

Higher lift requires higher valve spring loads (pressures) and flat

tappet cams can only handle so much. Additionally, increased rates of

lift (cam lobe velocity) above .007" per degree for example on an .842"

diameter G.M. lifter, would cause the lobe to reach-out over the edge

of the lifter's cam face. Consequently, with either too much spring

or too high a lift rate, most racers know that extremely radical flat

tappet cams will eventually self-destruct.

But, what about roller lifters? Are they as indestructible

as many believe? How do we prolong the life of their roller bearings

in today's modern race engines? Roller lifters require special care

and maintenance if they are to provide good service life. Here are the

3 most important factors you should consider to insure their success.

|

1. AVOID DRY "START UP": Roller lifter bearings are assembled

with a "tacky" rust-preventing grease that is not intended for lubrication.

Therefore, new lifters should have their roller bearings thoroughly

washed in clean solvent or acetone to completely remove this assembly

grease. After air drying, premium motor-oil (non-synthetic) such

as Kendal GT-1 should be used to pre-lube the bearings just before

installation.

2. AVOID "OVERLOAD": Increased load always

means reduced service life. Want 50% more thrust from a jet engine?

Ask Rolls-Royce or G.E. and they'll tell you to expect about one-fourth

the service life between overhauls. Similarly, employing drag race

valve springs in the 800, 900 to 1000 lb. range will reduce the life

of your roller bearings between rebuilds much the same as will employing

high-impact roller cam profiles.

3. EMPLOY A REV KIT : The primary advantage

of Camfather Ed Isky's invention of the 1950's is that by pre-loading

each roller lifter bearing to its respective cam lobe, you eliminate

needle roller bearing "skew". Skewing (the momentary mis-alignment

of the bearings' needle rollers to their respective races) is provoked

by the start-stop skidding action of the roller bearings each time

the lash is taken-up. Eliminate it and you extend roller bearing life

dramatically! Unfortunately, many engines such as the big block Chevy

which could use one the most, don't lend themselves to such an installation

because of the severe angularity of the pushrod coming out of the

lifter.

|