|

|

|

|||||

|

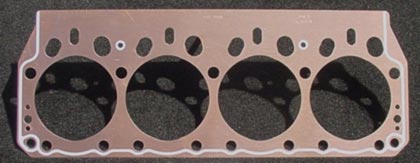

GLUING GASKETS & RTV Should you glue gaskets in place on engine parts? In trying to get a set of modified intake manifold gaskets cut into separate sections to stay in place on a head, it may be required. But in general it is really a matter of personal preference. Dorton has assembled engines gluing and not gluing gaskets in place, and says it hasn't made any durability difference. The glue of choice is usually 3M's (tm) Weatherstripping Adhesive - you know the stuff - it has the consistency of thick yellow phlegm and almost welds parts (including fingers) together on contact. It is also one of the hardest materials to clean off of parts, so use it sparingly and be prepared for extra clean-up time when removing gaskets you've set up with it. RTV silicone rubber is the flexible engine gasket material of choice and Dow Corning's 732 Multi-Purpose sealant is a popular RTV sealant of choice. It is also used as an adhesive to hold gaskets in place - oil pan gaskets in particular. Apply just enough RTV to fully seal a joint - you don't want a glob of it to shear or vibrate off and ultimately find its way into the engine's internals. You can also get a better seal between parts if you don't allow the RTV to "skin" before assembling the pieces - you want if fully malleable to fill a gap. COPPER POWER GUIDELINES For those racing with big doses of nitrous and boost, or both, a copper cylinder head gasket is the norm. Patrick Wilkerson of Flatout Racing Gaskets notes that copper has great blow-out resistance, and new materials on the market help seal the fluid passage holes of copper gaskets better than before. Patrick has these guidelines for choosing a head gasket based on V8 engine HP. They are generalized, but useful. A traditional composite head gasket without a wire ring ("combustion ring") is good up to 300 HP. For 300-800 HP a composite head gasket with integral wire ring can be used. From 800-1400 HP, a copper head gasket used with an O-ringed block deck (a high-temper stainless steel wire embedded in the deck) is the ticket. Over 1400 HP, a copper gasket with the O-ringed deck and a receiver groove added to the cylinder head (size and depth up to the engine builder) are necessary to contain the malleable copper. There is so much combustion pressure at this HP that it can lift the head, so you want to clamp the copper between the block and head for a useful seal. He states that the type of copper hardness used for the head gasket

depends on the condition of the head and block and the power generated.

Are they new or beat up? Make their condition clear when getting a copper

gasket recommendation from a vendor. He recommends a softer grade of

copper for better formability for the less than perfect engine and staying

in the 800-14oo HP range. Engines over 1400 HP generate so much combustion

pressure that it can lift the head and cause tremendous dynamic pounding

of head, block and gasket. Copper that is not too soft, used with a

wire and receiver groove, is the preferred combination to contain this

kind of power.

|

||||||

| Copyright 1999-2001, Drag Racing Online and Racing Net Source | ||||||