|

|

|

|||||||||||

It's What's Up Front that Countsby Sky Wallace |

||||||||||||

|

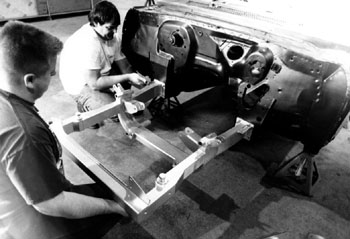

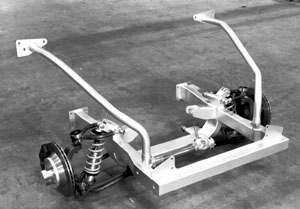

Okay so you finally found that "Deuce" you’ve been looking for and you have decided to turn it into street stormer that will also do duty at the drag strip. After looking at the front clip of this thirty-something Chevy you come to the realization that the stock front clip, suspension and braking are going to leave something to be desired. What the old Chevy is going to need is a front end that is stronger, lighter, offers better braking and more clearances for headers and other things. Chris Alston’s Chassisworks front-frame kit for GM’s 1962-67 Chevy II/Nova models meets all of those requirements. The Chassisworks front-end clip has been designed for assembly and installation with a bare minimum of common hand tools. No welding or special fabrication skills are required, which means you can do it yourself and save some of your hard earned cash.

Rather than dealing with the compromises involved in trying to make existing parts fit, the Chassisworks engineers basically started from scratch. Before the revolution in computer design and manufacturing capabilities, a project like this would have been impossible for anyone not linked with the Detroit automakers.

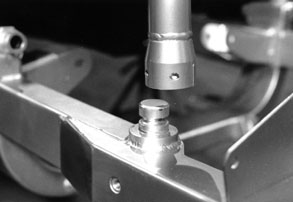

However, with computing power that far surpasses anything Detroit possessed when these cars were built, and with the extremely sophisticated CNC milling centers in the Chassisworks facility, all that has changed. Just about every part inthis kit simply did not exist before this project was started, and everything has been designed specifically for this purpose. In fact, more than 400 new parts were created in the process.

Instead of providing a set of blueprints that might be hard to follow and intimidating for the first-time builder, the NoFab kits come with photo-illustrated installation booklets that demonstrate each step of the conversion. Without the variables inherent when cutting-and-welding components combined with the fact that there is only oneway for these bolt-on assemblies will fit together to be assembled this is the do it yourself guys dream kit.

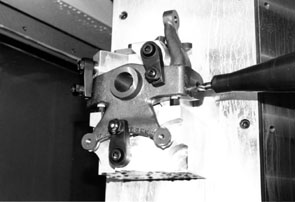

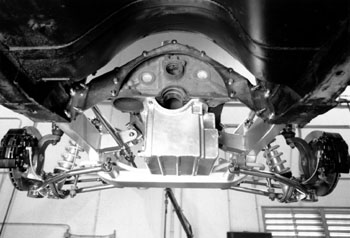

While the kit shown in the photos is for a Chevy II/ Nova by simply changing the width of the front crossmember, mounted A-arm suspension components will fit into a wide variety of cars, as will the company’s new billet-aluminum hubs, cast-iron spindles and brake rotors.

Chassisworks also designed and now manufactures its own steering rack, one that provides extra ground clearance while also allowing proper bump-steer control. The first rack in the industry built specifically for street machines, it is available in one-inch increments from 15.5 to 29.5 inches wide, to fit any car with a front-hub width that measures between 51 and 65 inches. This extra ground clearance could be very helpful when installing headers or if you have a deep sump oil pan.

In fact Chassisworks is manufacturing its own headers specifically for these cars. Chassisworks developed equal-length -style headers for both big and small block applications that clear all frame suspension and steering components, but an aftermarket "mini-starter" is required.

The car undergoing the transformation in these photos is a 1963 Nova. During it’s extended stay in the Chassisworks shop, this Nova also acquired a 4-link rear suspension and subframe kit, FAB9 rearend housing, 10-point roll cage with swingout sidebars, and new, wheel-tubbed interior tin with a steel driveshaft tunnel, all of which are found in the company’s catalog ($6 postpaid to Chris Alston’s Chassisworks 8661 Younger Creek Drive Sacramento, CA 95828)

The Chevy II/Nova kit we’ve shown you here is the first in a line of high-tech, NoFab products. Currently under development at Chassisworks are the next offerings, which will provide front clip help for first-generation Camaro and Firebirds and kits for 1968-74 Novas. Eventually, the company also plans to offer specific NoFab packages for popular street machines dating back to 1955. For further information, check out www.cachassisworks.com or call 800-722-2269.

photos by Sky Wallace

|

||||||||||||

|

Copyright 1999, Drag Racing Online and Racing Net Source |

||||||||||||