Now remember one important thing about this

combination: the pistons had small domes and

the cam just over a half-inch of lift. If you

have a lot of compression with a big dome on

the piston and a .650 lift cam you will have

to do all of the degreeing and checking we didn't

have to. Ditto for installing the lifters, push

rods and rocker arms. I just lubed everything

up well and installed them. If you've got high-dollar

solid lifter stuff there will be a lot more

work. Since putting the engine into the Vega

and racing it, Jok told me he basically hasn't

touched anything in the engine -- although he

did say that he felt so guilty that he actually

took the valve covers off once and ran the valves

just to make himself feel better.

We had the engine almost completely assembled

when we discovered that we had few extra Allen

head screw-in plugs left over. I had forgotten

to install the two threaded plugs that go behind

the timing chain assembly so I had to take that

stuff back off and screw those plugs in. We

also had a little brain cramp and got the upper

and lower bearing halves confused and had to

re-do that job.

I

figure things like that are just part of the

deal when you are doing it yourself (at least

when I'm doing it). It taught me to check everything

at least twice. After those two speed bumps

the rest of assembly process very smoothly...sort

of. We did have a problem with having enough

hardware and gaskets. I

figure things like that are just part of the

deal when you are doing it yourself (at least

when I'm doing it). It taught me to check everything

at least twice. After those two speed bumps

the rest of assembly process very smoothly...sort

of. We did have a problem with having enough

hardware and gaskets.

I had no idea that gaskets, especially those

Fel-Pro blue gaskets, were so expensive or that

manufacturers no longer include hardware with

their parts. If you are building an engine from

scratch you better set aside time and money

to buy all the nuts, studs bolts and fasteners

required. I had to make several runs during

the process to buy head bolts, head studs, bolts

to install the intake with, bolts for the pan

and headers, and an oil pump shaft.

Despite those minor glitches we had the motor

assembled and ready for Jok in just two days.

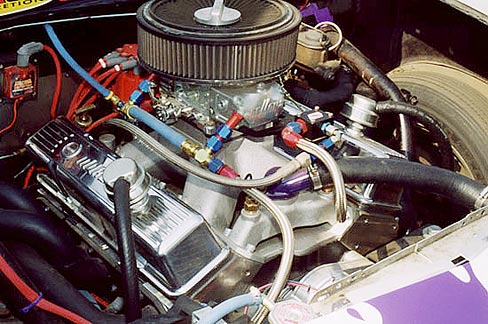

Once

the engine was bolted into the Vega it performed

better than we had expected. Jok put a Barry

Grant alky carb that we had used on the Project

4-Link dragster onto the Dart intake, hooked

up the MSD ignition that came with the Vega

when we bought it, and went to the track. Early

testing saw the Vega run the quarter-mile consistently

in the high 10.50's at 125+ and the eighth-mile

in the 6.60/100+ range. Once

the engine was bolted into the Vega it performed

better than we had expected. Jok put a Barry

Grant alky carb that we had used on the Project

4-Link dragster onto the Dart intake, hooked

up the MSD ignition that came with the Vega

when we bought it, and went to the track. Early

testing saw the Vega run the quarter-mile consistently

in the high 10.50's at 125+ and the eighth-mile

in the 6.60/100+ range.

Jok thinks that with a small roller camshaft

from Isky in the motor the Vega would run 9.90's

easily. In the meantime the engine the way it

is with a hydraulic cam that limits the engine

to 7500 rpm will probably last for a very long

time before it needs any maintenance.

Jok and I had budgeted about $13,000 to build

the Back to Basics Vega project and that included

the engine. As it turned out we probably got

close to that figure, but just barely. We have

about $4,500 worth of parts in the engine based

upon the retail prices and made an alky burning,

single four-barrel, 383-inch mouse motor that

has pushed our 3,000 lb Vega project car to

consistent 6.60/104 laps on the eighth and a

best of 10.59/125.60 in the quarter. According

to our charts the engine has to be making about

520 hp.

What I learned from this was that you can build

a "budget" engine using off-the-shelf

speed parts that will make plenty of power and

that you won't have to sell the kids into white

slavery to finance the project. The secret,

if there is one, is to trust what the manufacturers,

your local speed merchant, and machinist tell

you. Buy and install the parts they recommend

and stick to the basics.

| SOURCE

BOX |

Ohio

Crankshaft

5453 SR 49 Greenville, OH 45331

800-333-7113

www.ohiocrank.com

|

Isky

Racing Cams

16020 S. Broadway

Gardena, CA 90247-9990

213-770-0930

www.iskycams.com |

Dart

Machinery

353 Oliver Drive

Troy, MI 48084

248-362-1188

www.dartheads.com |

Moroso

Performance Products

80 Carter Dr

Guilford, CT 06437

203-458-0542

www.moroso.com |

Don

Kulash

Precision Engine Service

Glen Carbon IL

618-288-3779 |

Bill

Weckman

Weckman Racing Engines

Granite City, IL

618-876-1762 |

|