|

<<

PREVIOUS PAGE

This is significant when one recalls the incident

of Warren Johnson covertly measuring Larry Morgan's

new Stratus during testing at Las Vegas last

February; nothing more was said because the

car was legal.

"A Pro Stock car wants just enough down-force

in the front to steer it, and just enough in

the rear to keep the tires planted, so they

won't spin on the gear changes," says DeKoninck.

Also, the rear tires need to be packaged into

the back section of the car under specific guidelines;

NHRA has over 20 reference points they use to

verify a Pro Stock car against a production

model.

Similar to the previous funny car effort, CATIA

files were used to generate a 3/8-scale version

of the Stratus design.

|

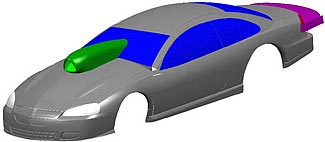

Here is a picture

of the Stratus in CATIA. The program allows

the car to be viewed from every possible

angle. |

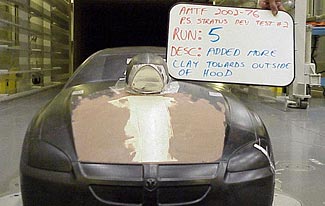

| Ready to go to work; you

gotta love the '200-mph' duct tape, which

is going to get a real torture test in the

wind tunnel. |

|

|

As the board

says, this is Pro Stock Stratus development

test #2, run #5, and the change is more

clay added to the outer edges of the hood. |

A Pro Stock Neon model was also CATIA-built,

using laser scanning (surface-scanning an existing

Pro Stocker) and then constructed to verify

data. DeKoninck and the model builders and stylists

were under a great deal of pressure to complete

the effort for debut at the start of the 2003

season, but, when it was done, the aero numbers

on the new body

ADVERTISEMENT

|

|

were

even better than those of the smaller Neon,

which had been designed primarily by hand. After

four full days in the tunnel, these changes,

which were verified as legal using a set of

3/8-scale NHRA-type body templates the designers

created, were returned to the CATIA program

using laser scanning.

Once finalized by NHRA, the CATIA design was

printed out from 20 different full-size angles,

and car builder Jerry Haas came to the Tech

Center to advise on cutting paths for the separate

panels (remember, the whole car was pictured),

flanging for assembly, and other construction-related

issues. Roush Composites again was called on

to cut the full-scale buck, and Haas began building

the first chassis using the drawings as a guide.

Like the funny car, the bodies are all carbon-fiber

or Kevlar, which requires vacuum-forming.

NEXT

PAGE >>

|