|

|

|

Four racing tips that can save you time, aggravation and $$$. Words and photos by Dale

Wilson

|

LEFT SIDE, PLEASE

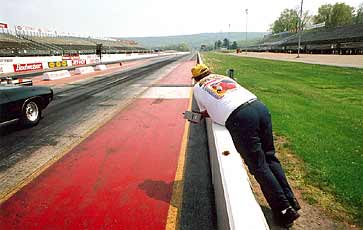

Check out this photo we took at the Grove. This savvy crewman has taken refuge behind the Grove’s full-length guard wall, well away from anything that might ka-bam or drop off the Camaro, far left. That’s the safest place of all. |

I always mount my dragster from the left side, just like in mounting a horse. Now comes an idea from my chassis builder Tommy Harris of Fabrication Concepts in Douglasville, Georgia, the craftsman who is building my new front-engine bracket dragster.

Notice that the savvy crewman always stands on the left (driver’s side) of the race car when said is doing a burnout or being lined up in the staging beams. Why? There is a good reason for that --- since a running engine rotates counterclockwise, anything that might fly off, say a starter ring gear or a piece of flexplate weld, will fly off to the right side, resulting in an injury to the crewman. Stand on the right side and an exploding engine, trans or flexplate will inevitably head for that side, while in most cases, the flying pieces will miss the one on the left side simply because of inertia will direct the pieces to the right. We’ve seen one spectator standing on the right side near a dragster doing a burnout get hurt when a flexplate piece exited the underside of the car and headed his way, resulting in a bruised and bloody leg.

And the lesson here is an added bit of learned logic --- spectators should stay away from any car doing a burnout, regardless of which side they’re on

HOLEY, HOLEY, HOLEY

In the photo, notice the four holes we drilled in an old thermostat. Our drill, drill bits and a piece of 2-by-4 wood lie on the driveway. It takes only a minute or two to complete this Joe Haddon Quik Trix. |

Footbrake racer extraordinaire Joe Haddon of Conyers, Georgia, gave us this Quik Trik. He kept having heating problems with his 10-second Chevy II, and tried everything to keep his small-block Chevy cooled between rounds --- squirting down the radiator, running the fan extra-long, adding water between rounds, etc. He finally came up with this simple idea. He took the thermostat out of the water neck on his intake and drilled four small holes in the thermostat. He found that it aided in the water flow to the engine and intake when he first starts the engine on a Saturday afternoon. The drilled thermostat also acts as a pressure release or a pressure balancer. His 180-degree drilled thermostat, he found, also modifies the water temperature to a degree (no pun intended). During the rest of the racing day, the “holey” thermostat, he found, gets the radiator water flowing past the thermostat, helping cool the engine that much more. This one is a cheap Quik Trix and should be used on an experimental basis. But hey, Joe says it works, and we believe him. He used to have his pit area covered with water from his water sprayer. No more.

DON’T GIVE ME NO LIP

| We used Fran’s hands as a model to show you the difference between the two dragster body panels. She is holding the front piece on our new Fabrication Concepts front-engine dragster, completed in 2004, while her dragster’s panels, circa 1989, are in the background. Note how my FED has the bottoms bent outwards, while her older digger’s panels tuck inward. Our rubber donut is placed underneath Fran’s dragster, and acts as a cushion in the trailer. |  |

It used to be that dragster builders rounded the lips of body panels to the inside --- down and under --- of the dragster’s frames as THE proper way to outfit the panels to the car’s tube frame. Not any more. Now most newly-built dragsters have a lip that bends outwards of the frame, and there is a good reason for that --- many dragster racers nowadays use a rubber “donut” that sits on the trailer floor between the dragster’s frame crossbar that is welded to the bottom of the frame around the driver’s compartment. The donut prevents the dragster frame from getting cracked and bent when being hauled around in the trailer. And with the body panels bend out, they don’t get bent or warped when the donut is set in place and the car lowered onto the top of it. Outer-rounded body panels also help when it becomes necessary to set the dragster on jack stands. We found this to be especially true when jacking up our new Fabrication Concepts front-engine digger for jack stands. Fran’s 1989-model dragster has the panels bent to the underside and inside of its frame rails, and we bent a couple of them before learning to place jack stands on the innermost part of its frame. Again, logic dictated this change among builders, and in this case, newer is definitely better.

ONE MORE SILVER HALF-DOLLAR

You wanna dig on a cool-looking valve cover? Check this one out. That purple

you see on this steel Chevy small-block valve cover came courtesy of our race

car painter and powder-coater Joe Sannutti of Premier Powder Coating at Baxley,

Georgia. This one and its sister will go on our “new” front-engine

dragster, the one we’re presently thrashing on to meet the June 18-20 2004

Holley Hot Rod Reunion presented by Du Pont Automotive Finishes in Bowling Green,

Kentucky. Yeah, the color is “extra bling-bling,” so call Joe at 912-366-0985

to get yours done and find out exactly what that color purple is called. He

has plenty of such “candy” colors available.

But there’s more to this steel valve cover than meets the eye. Notice where the breather hole used to be. Now sits in its place a Kennedy half-dollar that came from wife Fran’s coin collection. Notice too the new breather hole that takes the old one’s place. That and

|

|

Harris built a big breather/puke tank that now sits in front of our flat-mounted

radiator on our dragster. Since we had no need for the stock hole in the valve

cover, we found that the Kennedy half-dollar fit perfectly in the hole. Tommy

welded it in place from the back side, then drilled and afixed a _-inch pipe

in the front of the valve cover, to take care of any liquid or condensation

that might come forth from our small-block Chevy engine. It will be routed into

the puke tank via two _-inch hoses. It all looks so nice, so nice … just

make sure to use a half-dollar in the hole’s place. A quarter won’t

work. ![]()

Copyright 1999-2004, Drag Racing Online and Racing Net Source