|

|

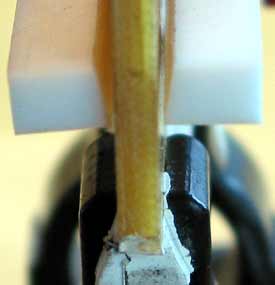

| The vanes (this is a GZMS Super-Pro,

three-vane pump) are carbon-fiber and are attached to

“connecting rods” whose roller bearings ride

on the crank. |

Several aftermarket companies had been making drag racing

evacuation or vacuum pumps for some years featuring vane-type

operation, in which blade-like vanes slide in slots in the

central armature. As the pump spins, centrifugal force makes

the vanes come out to contact the interior of the pump, where

they drag across the surface to pump air, like a little blower.

Zucco learned that the constant drag of the vanes in centrifugal

pumps causes some parasitic losses, and that these losses

increased with rpm. Further, the pumps didn’t seem to

work well with oil vapor. The centrifugal pumps tended to

get sticky and needed cleaning after almost every meet. GZ

Motorsports now markets a complete line of brand-new vacuum

pumps for racing that encompass a different way to use vanes

in an air pump.

|

| As modified by Zucco for racing

use, the vanes seal to the drum with strips of solid Teflon

that act like rings on a piston in the environment of

crankcase vapors. Equipped like this, pumps can handle

high-rpm use for several years before needing any service. |

GZMS’s Sportsman, Pro and Super-pro pumps are based

on brand-new Ford AIR pumps that have an armature rotating

in an eccentric motion, while the vanes slide in and out of

slots in the armature. When the crankcase vapors reach the

intake port of the pump, they are picked up in the large side

of the chamber and carried around to the smaller side, and

hence pressurized before they reach the outlet port. The big

difference between this and the other available racing vacuum

pumps is that in this case the vanes do NOT touch the inside

of the housing. They come very, very close but do not have

the material-to-material friction that, according to engineer

Zucco, is one of the causes of durability and efficiency problems

with conventional aftermarket vacuum pumps.

After considerable research in the world of pumps and vanes,

Zucco found that the OEM carbon parts were failing in high-rpm

use. Where the vanes move in and out of the slots in the armature,

they are in contact with seals on each side and a spring.

In the Toyota pumps, the plastic vanes were destroyed when

oil mist would ruin the carbon seals, which in turn would

wear enough that the springs would come out, immediately grenading

the pump. Everything he has learned through research and track/dyno

testing goes into his improved pumps that are a far cry from

the rebuilt import smog pumps he started with.

|

| We think of crankshafts as having

offset throws, but the crank for these vacuum pumps is

a straight shaft. As the drum is rotated inside the pump

case, this stationery but offset shaft cause the vanes

to go in and out of the drum. |

GZ Motorsports blueprints brand-new Ford pumps, modifies

the inlet and outlet ports for more efficiency, makes provision

for attaching rubber or braided hoses, and replaces a number

of components inside the pump with parts made from pure Teflon

for superior sealing and high-rpm durability. The Ford pumps

have durable carbon-fiber vanes. A newer material promises

to give even longer pump life than the Teflon seals, and is

undergoing testing right now. All pumps are tested and dated

before delivery, and most are packaged with a complete mounting

and drive system. You can find all the small-to-large Chevy,

Ford and Mopar applications on the GZ Motorsports website,

and they also work with anyone who needs something for a special

application.

Experience with their many drag racing customers has give

GZMS a research base that helped develop their application

chart. You might think that if some vacuum is good, then more

is always better, but the pump does need to be matched to

the application. There is such a thing as too much vacuum

in the crankcase! The engine’s need for crankcase vacuum

is dependent on several factors, including the amount of blowby

(from wear and ring design, i.e. low-tension or not), displacement,

rpm range and whether there is a power-adder involved. When

you’ve got a blower or lots of happy-gas, there is going

to be more “windage” in the oil pan, and your

engine will need better evacuation to reach its full potential.

Conversely, if a pump is too big for the application, the

parasitic losses can outweigh much of the horsepower gains

from the vacuum pump, especially if your engine builder used

conventional rings, because vacuum pumps show their biggest

gains on engines with low-tension rings.

In Part Two of this story, we'll look at choosing the right

pump for various applications, and how an effective system

is plumbed and completed.

|