|

There’s more here

too: Total Seal uses a Gapless ring set that measures (for

example) 0.0469-inch thick. This ring package is then coupled

with a spacer of 0.031-inch, installed at the top of the groove

to take up the difference in a 5/64-inch groove.

|

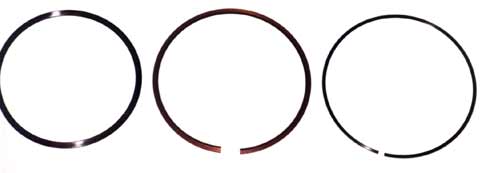

Part of

the Advantage system is this Gapless second ring. It differs

from others available in that the construction is very

simple. The primary second ring incorporates a ledge that

acts as a receiver for the smaller sealing ring. When

used in tandem, this second ring combination eliminates

the gap. The end result is a definitive lack of blow-by

coupled with increased levels (some times considerable)

of manifold vacuum. Note too, that a spacer is used in

conjunction with the second ring package. |

|

|

There is something you should be aware of when it comes to

Gapless rings: They’re either used in the top groove

or the second groove. Not both. And rings designed for the

top groove cannot be used in the second groove or vice versa.

One other point to consider is this: When switching to a Gapless

ring, there may be tendency for the PCV system to become seemingly

more efficient. What’s really happening is the ring

seal is causing the engine manifold vacuum to improve. You’ll

likely notice this phenomenon if you have a vacuum gauge installed

in your car.

While the oil ring used in the Total

Seal system first appears to be standard issue, there is an

important difference: Both the expander and the rails are

narrower than normal. This results in reduced friction, however

oil control isn’t sacrificed.

The oil ring used in the Advantage Ring System is called

a “Gold Power” ring (obviously, because the expander

is gold in color). It’s different than most conventional

oil rings, however. Gold Power rings do not fit as deep as

regular oil rings. This design is based upon narrower rails

and a narrow expander. The result is reduced friction, but

at the same time, the configuration maintains oil control.

The only catch with this type of ring is the installation.

Due to the narrow design, you have to be careful when installing

the piston in the bore. If you’re not paying attention,

the small rails may not stay in place. The bottom line here

is to watch the ring carefully as you push the piston through

a tapered ring compressor or when you squeeze the piston ring

combination with a band style compressor.

Does the new ring combination work? Most of the Stock Eliminator

racers we spoke with aren’t talking (and neither are

the Winston Cup teams which are using a similar arrangement).

But at least one Pro Stock engine builder is. They wish to

remain anonymous, but apparently the benefits of Total Seal’s

rings haven’t escaped them: A version designed for Pro

Stock is now used exclusively in their engines. The result

is the engines now make full power on the first dyno pulls

(instead of five, six or seven pulls later). Maintenance factors

have also improved markedly. In the end, there could very

well be something of interest to the little guy racer. Investigate

this stuff folks. You might be surprised at what you find.

|