|

By Mike Bumbeck

Photos by Mike Bumbeck and

RPS Performance Products

9/29/05

eat

is the sworn enemy of the clutch out on the 1320. Friction

created by the engagement of the clutch disc material to the

flywheel friction surface and pressure plate releases heat

as it transitions the energy of the engine into ground pounding

power. Too much power for the clutch setup, and the clutch

will start to slip and create more heat. More heat will cause

the clutch disk material to lose efficiency and slip more

– creating even more heat. eat

is the sworn enemy of the clutch out on the 1320. Friction

created by the engagement of the clutch disc material to the

flywheel friction surface and pressure plate releases heat

as it transitions the energy of the engine into ground pounding

power. Too much power for the clutch setup, and the clutch

will start to slip and create more heat. More heat will cause

the clutch disk material to lose efficiency and slip more

– creating even more heat.

Excessive heat can burn up the clutch and put everything

back on the trailer or on the tow hitch. Even worse, things

can get dangerous. Some early AA Fuel Dragster "slipper"

clutches created so much heat that they turned into white-hot

circular shrapnel, shearing the cars in half. Just ask "Big

Daddy" Don Garlits, who cooked up the design for his

rear engine dragster while in the hospital recovering from

a fiery clutch explosion that destroyed his dragster and nearly

destroyed him.

While clutch technology as it applies to drag racing has

come a long way, heat is still the enemy, and can bring a

world of frustration to the table whether you're rowing through

the gears on a bracket car or trying to figure out how to

get thousands of nitromethane induced horsepower down to the

ground without you or your clutch setup getting burned. Finding

the right combination of friction materials and clamping force

for consistent launches that won't turn the transmission into

an expensive rock tumbler is the goal.

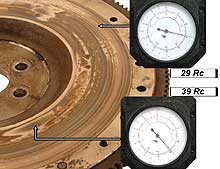

A factory Mustang flywheel shows

the difference in material hardness. Variances in can

remain even after the surface is machined flat, causing

corresponding difference in grip. This degree of overheating

can also result in flywheel shatter. |

SUPER FLY

Drag racing puts some heavy-duty demands on every component

of the clutch, but the flywheel takes the first and biggest

hit. Tremendous heat is generated on the friction surface

of the flywheel – especially if slipping the clutch

off the line is part of the race program.

Stock cast-iron flywheels are not only heavy, but can quickly

overheat, and are not rated to hold up to above stock RPM

demands. Think hot shrapnel again. A chromoly flywheel is

stronger and can therefore be made thinner and lighter, but

the steel surface is harder, which can lead to friction issues.

An aluminum flywheel with a steel heat shield friction surface

insert gets around these problems, but can create another.

The heat shield has nowhere to expand except against itself,

and can warp with extreme heat. This warping creates high

spots on the flywheel friction surface. This can cause slipping.

The slipping compounds the problem, as the heat created channels

through the high spots instead of being wicked away evenly

throughout the entire friction surface.

|

A used up heat shield

hoop from an aluminum flywheel shows the degree of warping

that can occur. Five to seven thousandths of an inch are

all it takes for a flywheel surface to start causing heat

and grip issues. |

|