|

Installment #5:

This month we update the

budget, install Lexan windows, finish the wiring

and install some fuel system parts

Words and photos by Jok Nicholson

5/7/03

We left off last month getting some suspension pieces installed and since then I have got the car back from the body shop and started putting it back together. Things like headlight doors, interior door panels, door handles, new dzus fasteners, etc. We spent about a week getting this done. Next up were the windows.

I had cut and installed Lexan windows on my trusty old '68 Dart several years

ago so I already knew what I DID NOT want to

do. I had already decided these windows would

be 3/16" Lexan. I called a local plastic distributor,

Regal Plastics, and asked if they could get

me 3/16 mar-resistant Lexan. Their answer was

"How much do you need, we stock it".

|

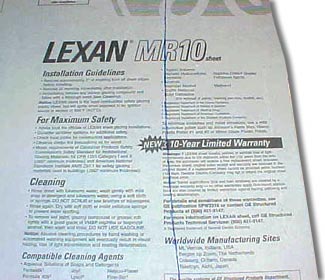

This

is how the Lexan MR10 arrives. Protective

covering on both sides and a crystal

clear product under the

protective covering. |

|

That was easier than I thought it would be.

I talked to the guy at Regal Plastics and we

decided on MR10 Lexan. It has a very scratch

resistant surface and can be cleaned with spray-on

Lexan cleaner and a soft cotton rag for best

results. The main thing I learned about Lexan

is if the window is very dusty, rinse it off

with water before trying to scrub the dust off

with a rag. Just use common sense; it is still

a plastic product, not glass.

Making the pattern for your windows is the

most stressful thing about Lexan windows. If

it is too small it is an expensive OOPS! I used

the old Plexiglas windows as a starting point

and traced them about 1-inch bigger all around

on some pretty stiff white poster board from

Wal-Mart. I used these templates and kept trimming

them until I was satisfied with how they fit

the openings.

Next up was the actual cutting. I used an inexpensive

variable speed saber saw and a fine tooth metal

cutting blade. I learned the last time that

a coarse blade will cut faster but the edge

ends up all chipped up and takes a lot of finishing

work with a hand file to look good. I also put

three layers of gray Racer's Tape on the bottom

of the saber saw so it would not scratch through

the protective covering that comes on the Lexan

and scratch it. Take your time as accuracy counts

and will save you hours of finishing the edges

with a hand file.

This is the variable speed saber saw I

used. Nothing special just put a few layers

of tape on the metal bottom plate and

a metal cutting blade with about 24 teeth

per inch and start cutting...very carefully.

|

This is the AuVeCo weather stripping I

chose. It is 1/2-inch thick and 1/2-inch

wide and one side had adhesive on it.

Worked great and is readily available

at auto body supply stores. |

NEXT

PAGE >>

|