|

Installment #6:

We build a transmission

Words and photos by Steve

Oldani

6/6/03

hope in this article to show more details in

the process of building a Powerglide transmission.

For some other basics, you can refer to my previous

"Trick Tranny Tips" here on DRO. I got a phone

call from my long-time friend, Jok Nicholson,

advising me he and his son were on the way with

a carload of JW Performance transmission parts

for me to assemble for the "Back-2-Basics" Vega

he is currently constructing.

hope in this article to show more details in

the process of building a Powerglide transmission.

For some other basics, you can refer to my previous

"Trick Tranny Tips" here on DRO. I got a phone

call from my long-time friend, Jok Nicholson,

advising me he and his son were on the way with

a carload of JW Performance transmission parts

for me to assemble for the "Back-2-Basics" Vega

he is currently constructing.

We went over what the goals and intended use for the trans would be, and then set out a plan of attack. I still had the 1.76 gears and 180 of the lovely little needle bearings they require in the box, left over from when I installed the 1.80 straight-cut gearset in the Project 4-link dragster trans some time ago.

Jok

had all of the needed parts to assemble the

planetary, including the new billet output shaft

carrier, and the pins and lock-plate for them.

I first used Dykem and a punch to set up the

locations to drill and tap the front of the

carrier housing for the three screws which retain

the lock-plate for the aftermarket pins. After

these were done, all parts were washed and,

after a liberal application of gel lube to the

180 needle bearings, the new washers and the

gears were assembled into the carrier. Then,

I added in the bleed holes to the case crescent

area. The reverse piston was installed in the

case, and then the reverse clutch assembly was

put in. Jok

had all of the needed parts to assemble the

planetary, including the new billet output shaft

carrier, and the pins and lock-plate for them.

I first used Dykem and a punch to set up the

locations to drill and tap the front of the

carrier housing for the three screws which retain

the lock-plate for the aftermarket pins. After

these were done, all parts were washed and,

after a liberal application of gel lube to the

180 needle bearings, the new washers and the

gears were assembled into the carrier. Then,

I added in the bleed holes to the case crescent

area. The reverse piston was installed in the

case, and then the reverse clutch assembly was

put in.

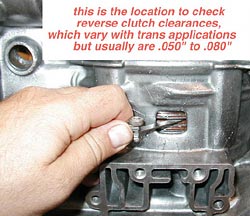

There

is a small "window" under the valve body area

of the case where you can check the reverse

clearances, as shown in the photo. Once this

was checked, then the high gear drum and clutches

were assembled and checked for correct clearances,

as shown in the photo. Then the drum was installed

after placing the Torrington bearing under the

flange gear, on top of the planetary center

gear. The low band was then put in over the

drum, and the dual-ring low gear servo was assembled.

I omit the stock cushion spring and small washer,

and replace them with a washer so there is no

play between the servo piston and the servo

piston shaft. Then, the pump was taken apart

to double check things. There

is a small "window" under the valve body area

of the case where you can check the reverse

clearances, as shown in the photo. Once this

was checked, then the high gear drum and clutches

were assembled and checked for correct clearances,

as shown in the photo. Then the drum was installed

after placing the Torrington bearing under the

flange gear, on top of the planetary center

gear. The low band was then put in over the

drum, and the dual-ring low gear servo was assembled.

I omit the stock cushion spring and small washer,

and replace them with a washer so there is no

play between the servo piston and the servo

piston shaft. Then, the pump was taken apart

to double check things.

NEXT

PAGE >>

|