|

<<

PREVIOUS PAGE

It is always a good idea to disassemble things

even if new, just to confirm they are as they

should be. There are photos showing where the

stock downshift timing valve is located, and

it needs to be removed for race trans applications.

Also, photos show the location of the converter

feed passage, and the pump priming valve roll

pin, which needs to be staked in place, or replaced

with a better pin to secure it in place. I again

apply a good amount of gel lube to the front

pump Teflon sealing rings.

After the pump is ready, I like to use a guide

pin to align the pump gasket and install the

pump with. When using the Ultra-Bell, always

use some RTV sealant under the bolt heads as

it will prevent headaches later! Always use

a torque wrench as well, on ALL fasteners in

a trans. Once the pump was on I used a caliper

to measure the end play,  which

can be adjusted with shims at the pump, or under

the rear Torrington bearing at the output shaft.

Then, I installed the late-model rear support,

along with the correct gasket, and plate under

it as well. The photo (right) shows the difference

in the early and the late supports, as well

as the gasket and plate. Use only the late-model

support with the gasket/plate if you are using

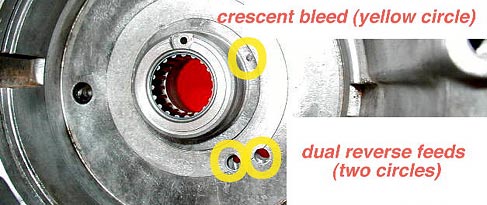

a dual-passage brake. Another photo shows the

inside of the case, and identifies the dual

feeds, and also where the crescent air bleed

comes in to the case, behind the reverse piston. which

can be adjusted with shims at the pump, or under

the rear Torrington bearing at the output shaft.

Then, I installed the late-model rear support,

along with the correct gasket, and plate under

it as well. The photo (right) shows the difference

in the early and the late supports, as well

as the gasket and plate. Use only the late-model

support with the gasket/plate if you are using

a dual-passage brake. Another photo shows the

inside of the case, and identifies the dual

feeds, and also where the crescent air bleed

comes in to the case, behind the reverse piston.

Then, I disassembled the valve body, again

to confirm all was okay, and then installed

it to the case, being sure to line up the tube

from the body to the case, and the shift linkage

pin  into

the manual valve. The photo (left) shows the

orientation of the shifter linkage inside the

trans. After torquing the valve body, the filter

extension and filter were installed, along with

a deep cast-aluminum pan, which holds an additional

two quarts of ATF. into

the manual valve. The photo (left) shows the

orientation of the shifter linkage inside the

trans. After torquing the valve body, the filter

extension and filter were installed, along with

a deep cast-aluminum pan, which holds an additional

two quarts of ATF.

Then, the low band was adjusted. The correct

procedure is to tighten the center bolt in to

72 inch/pounds, then back it out 3 1/2 to 4

turns, and snug the lock nut. At the same time,

I snugged the outer lever on the 2-piece shift

lever. Then, the tailshaft housing was installed.

That pretty much wraps up the build of Jok's

1.76 trans, which should be bulletproof for

his Back-2-Basics Vega.

SOURCE BOX:

Oldani Motorsports

328 Drynan Drive

Waterloo, Iowa 50701-1622

oldani@forbin.net

319-233-5677 (8-10 PM Central time)

|