|

Because the dragster is so long and low, loading it into the trailer

was a different deal altogether. The first requirement was to remove

the fiberglass nose from the dragster and jack up the front of the trailer

as high as the trailer jack could get it. Of course, this made it more

difficult to step up into the side door of the trailer. My old trailer

also had a beaver tail floor; (the rear of the trailer drops five inches

the last four feet) which is great for most cars, but a real pain for

a dragster. To overcome this obstacle, I laid two eight-inch wide, two-inch

thick, six-foot long boards on the trailer floor so as I drove the dragster

into the trailer the front tires would ride up on these boards and the

middle of the dragster body would clear the beavertail section. After

doing this for two years, I thought there must be a better way!

Finding the better way took some luck, both good and bad. The bad luck

came first. When my wife Colleen and I were traveling through Georgia

last summer, my trailer broke a wheel bearing and this ruined an axle.

Through Dale Wilson and racing friend Peabody Harrel, I got hooked up

with Jeff Smith at Haulmark Trailers to repair the damage. This was

my good luck. While my trailer was being repaired I had time to discuss

with Jeff the problems of loading my dragster. My timing was right,

Jeff said he had some ideas to alleviate these problems and when I was

ready to order a trailer to give him a call.

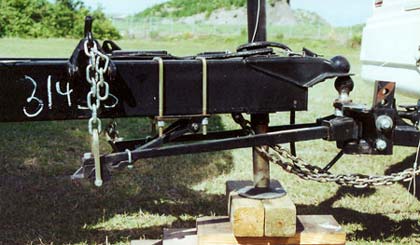

At the end of the 2000 racing season I made an agreement to sell my

trailer to my friend Victor Ferra and then I gave Jeff Smith a call

and ordered a new 30-foot Haulmark Edge with the special "dragster package.'

As Jeff explained, this package incorporated some new design features

and construction techniques to lower the floor of the trailer, which

would decrease the angle of rise that the dragster has to overcome when

being loaded.

|

|