|

Words

and photos by Dale Wilson

3/11/04

|

Sometime around

late 1990, I took over the reins

of Bracket Racing USA magazine from

friend and mentor, the late Steve

Collison. It was what I prepared

my life for since I graduated college

in Florida with a degree in magazine

journalism. It was cool. Plus I

could do just about what I wanted

to do, as long as I didn't make

anybody REAL mad, satisfied the

advertisers and kept the bosses

up in New Jersey happy. I succeeded

on all three counts.

|

|

So the first thing I did was call up my buddy Wayne Scraba in British Columbia, a chap who was an ex-Royal Canadian Mounted Police turned racer and an all-around automotive whiz, and told him I wanted him to do a monthly column on tech stuff. "Let's call it something catchy, like 'Quik Trix,' something an average bracket racer can read and learn something about in 10 minutes max," I said. "Make it two pages long, you supply the photos unless a manufacturer gives you some." Scraba now contributes tech to DRO.

Those two-page, quick-read "Quik Trix" lasted for 68 issues of Bracket Racing USA, and they were my favorite part of the book. Bracket Racing USA was killed in 1999 or so when the company was sold to a corporation in California that came up with Drag Racing USA, which was also killed a couple of years later. But I always thought that "Quik Trix," or "Pit Tips" or any derivation of the same was a great idea. Still do.

In that spirit, I'm going to give you-all five all-new "Quik Trix" that I've recently gleaned from our hours building our new front-engine dragster, and working on wife Fran's '89 Suncoast rear-engine dragster. More may come later on in the year, but for now, read 'em and learn. If you have some yourself, feel free to let me know about them. I figure any ol' racer can learn a few new tricks -- um, make that "Trix."

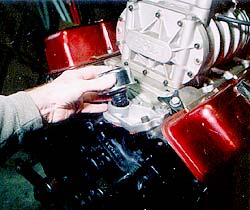

CAP IT OFF

I have had my small-block Chevy engine sitting on the engine stand and ready to go into my new Tommy Harris/Fabrication Concepts-built front-engine dragster for nearly two years now. It is sitting there, less carburetor and headers and protected by a plastic wrap that came from my local machine shop after all the machine work was done. It hasn't moved since.

It is also somewhat dusty down there in my basement, and that's the reason

for the plastic wrap. But since the MSD 8555

distributor is not mounted on the back of the

motor, the distributor hole is open, providing

a good opportunity for dust to settle in when

the plastic wrap is not on the engine.

Recently,

I changed oil pans on the engine, removing the

wrap for a couple of days. The white masking

tape that I affixed over the distributor hole

had almost disintegrated by then, so I had to

come up with something to cover the hole and

keep all the dust out. Poking around, I found

that a Chevy valve cover breather with a rubber

grommet attached fit nicely into the hole, doing

away with the crumbly masking tape and the potential

for trash and dust to get inside the motor.

Try this yourself. Just don't expect the breather

to stay in place if you have to turn the engine

upside down on the engine stand. Recently,

I changed oil pans on the engine, removing the

wrap for a couple of days. The white masking

tape that I affixed over the distributor hole

had almost disintegrated by then, so I had to

come up with something to cover the hole and

keep all the dust out. Poking around, I found

that a Chevy valve cover breather with a rubber

grommet attached fit nicely into the hole, doing

away with the crumbly masking tape and the potential

for trash and dust to get inside the motor.

Try this yourself. Just don't expect the breather

to stay in place if you have to turn the engine

upside down on the engine stand.

|